Polypropylene can be difficult to bond with standard adhesives. Permabond developed the Permabond TA46XX range to bond low surface energy plastics. Permabond TA4605, TA4610, TA4611, and TA4631 all bond untreated polyolefin surfaces. These adhesives are ideal for bonding polypropylene and polyethylene – without the need to carry out costly surface pre-treatment

before bonding. They can also be used to bond polyolefins to a wide variety of other substrate materials.

What is polypropylene – PP- Polypropylene is a polyolefin plastic material that is challenging to bond, thanks to its low surface energy. It is low-cost and versatile, so its use is extremely common.

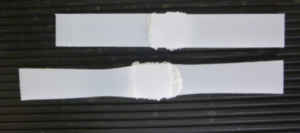

Polypropylene Lap Shears Bonded with TA4610 | The PP Stretches and the bond remains!

Permabond TA4610 forms bonds that cause the polypropylene to stretch and fail before the bond breaks.

For untreated polypropylene there are several options:

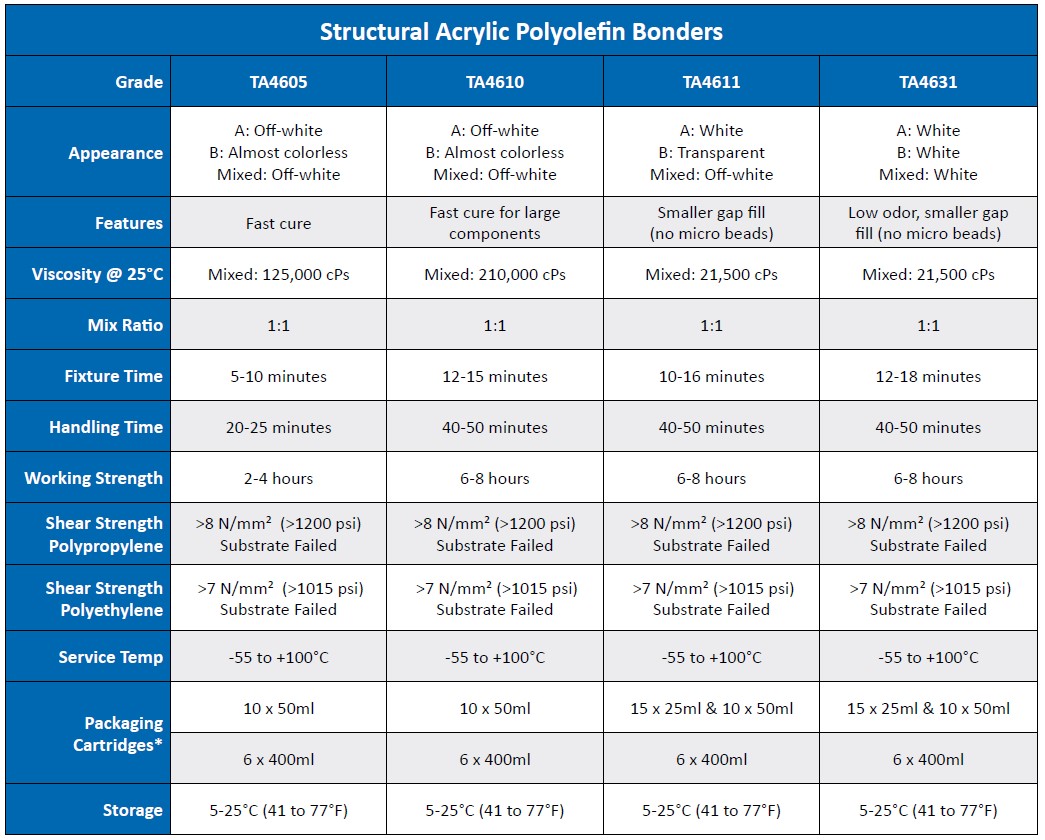

a) Bond untreated – select Permabond TA4605, TA4610, TA4611, or TA4631 structural acrylic products; these are developed especially for low-surface energy polyolefins. Download the flyer!

b) Or prime with Permabond POP and use with cyanoacrylate adhesive only

(other adhesives are not compatible with POP).

c) Of course, you can consider flame, corona or plasma treat the surface in order to use other adhesive types.