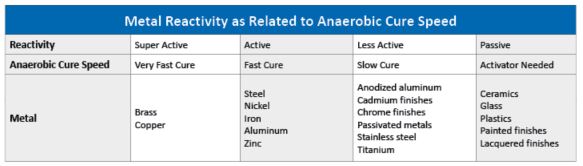

We identify anaerobic adhesives (AAs) by the job they perform; threadlocking, thread sealing, retaining compounds, & gasket makers. They cure only in the absence of oxygen and the presence of metal. Similar to cyanoacrylates (instant adhesives), there is a maximum gap that anaerobic adhesives will cure through. Controlling that gap is critical to achieving full anaerobic curing. The speed of the cure is related not only to the gap but also to the reactivity of the metals being used. For example, brass is more reactive than steel which is more reactive than anodized aluminum.

The following shows typical cure times for an anaerobic threadlocker at 23°C. Note copper will follow the faster cure curve, whereas passivated surfaces like stainless steel will be closer to the slower cure curve. Lower temperatures and larger gaps will reduce anaerobic curing speed.

Surface conditioners can activate inactive surfaces to allow or accelerate the cure. Note you can activate parts with ASC10 up to 30 days prior to applying the anaerobic adhesive or sealant.

For more information on anaerobic adhesives, click here or Contact us so we can help you select the right adhesive for your application.