Some common uses have come to pass due to our customers’ unending creativity and our technical staff’s unrelenting curiosity.

Crime Scene Investigation

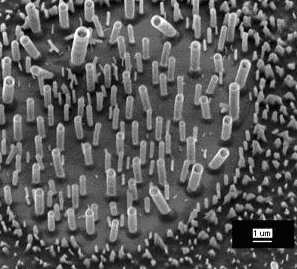

Crime Scene InvestigationOften fingerprints left at a crime scene are not visible impressions that can be photographed. Invisible fingerprints are called latent prints. So how does cyanoacrylate adhesive make latent prints visible and useful to law enforcement? These adhesives are incredibly reactive liquids. Stabilizers keep them liquid. Very small traces of moisture deactivate the stabilizer and allow the adhesive to cure. Small quantities of curing adhesive can volatilize and then fall back to the surface, creating a blooming or frosting effect.

For most customers, this is unsightly- and we’ve gone to great lengths to create a low odor, non-blooming line of adhesives. For crime scene investigators, it is this otherwise undesirable feature that creates the print. Standard ethyl cyanoacrylate adhesive can be used, but for maximum print visibility and maximum speed of developing the print, Permabond formulated a specialty grade for law enforcement. To learn how to collect fingerprints with Permabond special high bloom grade CPP621, click here.

3D Printing Infiltrating

3D Printing InfiltratingGranular 3D print methods produce 3D printed components that remain powdery and fragile unless coated. To improve their appearance and strength, they are dipped into cyanoacrylate adhesive. The adhesive infiltrant wicks into the porous model and cures to a hard solid piece. Unlike the crime scene adhesive, 3D print infiltrants need to be very low odor with low blooming effects. Depending on the type of printing, various products are available with ultra-fast cure, high gloss surface, fast cure with good penetration and brilliant color, and a delayed set product that provides maximum strength and a matte surface. (Link to 3D infiltrant 031616)

Many years ago, an organization I can’t mention contacted Permabond to bond something I can’t talk about to the bottom of an item that was in the water. Chemists brainstormed, and all agreed that there was no solution – at Permabond, that is when the fun begins. Tip – if you want to get something done, simply tell a chemist it isn’t possible.

The solution was a surprise… cyanoacrylate! We thought they had gone daft. How can you bond something underwater with a product that cures with water? As it turns out, if you put a glob of a high viscosity adhesive onto a part and then put it under water, it will immediately form a shell of cured adhesive on the surface – but the adhesive under that shell will remain viable longer. Once underwater, smash the part with the glue glob on it to the boat so the glue shell bursts and the liquid inside it can bond the two components.

Cyanoacrylate adhesives cure with moisture, but the cured adhesive isn’t incredibly resistant to water. In the adhesive business, we call bonds that must perform with long term water contact “fish tank” applications. We never recommend a cyanoacrylate for a fish tank application – but wait – cyanoacrylate adhesives are used to bond coral into fish tanks all the time. Cut branches of hard corals are glued onto a piece of reef coral, again, this is often done in the tank. The new piece of coral is held in place while it sets it’s “roots” through and around the cyanoacrylate; by the time the adhesive dissolves, the living coral is firmly attached to its new home.

Cyanoacrylate adhesives are desirable because they are single component, instant curing, non-flammable, and bond most materials. When given the option between this simple solution and an adhesive that needs mixing, heating, a two step process, etc… most prefer cyanoacrylates. But cyanoacrylates have some limitations; let’s have a look at them.

Because of their brittleness, cyanoacrylate adhesives aren’t generally ideal for structural applications. Nevertheless, cyanoacrylates off-set the slower cure time of other adhesives in processing. How does this work? Many applications that require the structural toughness and durability of, say, a two component epoxy benefit from also using a cyanoacrylate. Simply assemble the parts with two component epoxy, then tack them together with cyanoacrylate. This eliminates the need for clamping or jigging as the epoxy cures, because the cyanoacrylate is holding it fast in place.

Similarly, cyanoacrylates hold o-rings in place during shipping. In many applications, the o-rings are bonded in place. In other applications, the o-ring will be in compression in the unit, so the cyanoacrylate isn’t required to maintain the o-ring’s position during the rugged equipment use or underwater but is used to prevent the manufacturer from receiving complaints due to the o ring being lost in transit or forgotten in assembly.

While on this topic – many folks form o-rings by splicing and bonding with cyanoacrylate. Yet another clever use.

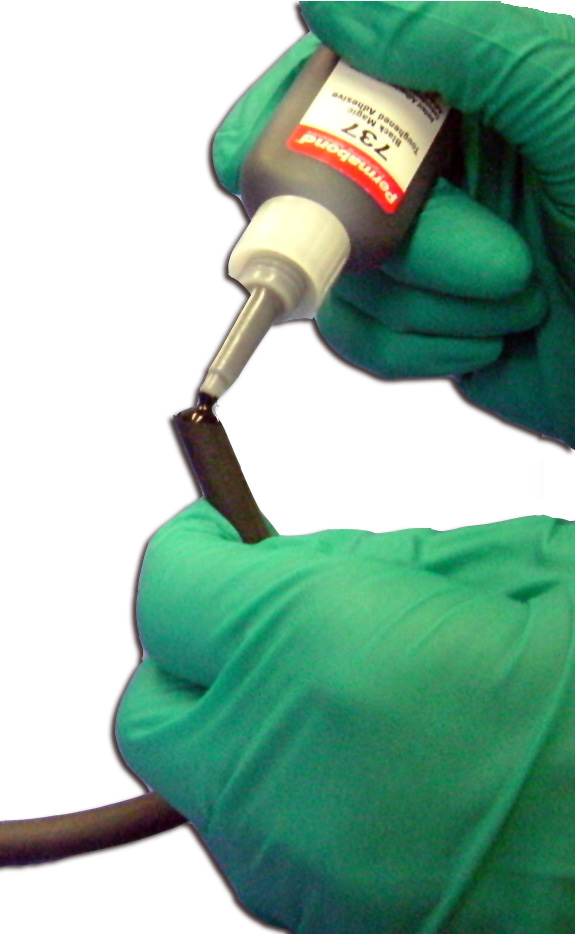

Wire tacking and strain relief are common applications for cyanoacrylate adhesives in everything from speakers to motors to electronics. Again cyanoacrylates cure by reacting to the traces of moisture on the surface they are bonding. When used in tacking applications, an accelerant or setter cures the surface.

In addition to suture replacement, there are many surgical cyanoacrylate uses in medicine. Absorbable grades are even used to advance medical technology. Butyl cyanoacrylate is common in veterinary medicine for surgical wound closure and to close the wounds from cat declawing etc…

Cyanoacrylates bond fingernails and eyelashes.

Cyanoacrylates bond the pads of clarinets and saxophones, as well as produce the shiny finish on guitars. The adhesive provides specific acoustic benefits to the wood.

Although 910 is still a flagship, super strong, methyl cyanoacrylate, many other types of cyanoacrylates are available today. Listed below are types and cyanoacrylate uses.

Methyl Cyanoacrylate – 910 is a pure methyl cyanoacrylate that forms strong bonds to metals

Ethyl Cyanoacrylate – there are several types

Butyl Cyanoacrylate – Medical and Veterinary applications

Octyl Cyanoacrylate – Medical applications

Those are the common straight chain cyanoacrylates. However, the possibilities expand when we take side groups into account. Alkoxy alkyl cyanoacrylates provide additional benefits such as low odor, low bloom, and increased flexibility.

Do you have a unique bonding requirement? Please let us know if we can assist you.