What is Acrylic? (PMMA) – polymethyl methacrylate – Several types of industrial adhesive bond acrylic. Because its surface is receptive to adhesive bonding, bond strength typically exceeds the substrate strength (when the joint is pulled apart, the substrate breaks before the adhesive joint). Most applications involve clear acrylic, so a crystal clear, non-yellowing adhesive is normally preferred. There are many industrial adhesive options.

Cyanoacrylate – All grades adhere well to acrylic. Due to acrylics’ susceptibility, to bond acrylic with cyanoacrylate, it is important to use cyanoacrylate adhesive sparingly. When operators try to wipe excess adhesive outside the joint away, it will fog the acrylic. Cyanoacrylates offer a rapid cure in seconds and do not require any mixing or curing equipment. These adhesives are perfect for high-speed production lines. Limitations – maximum gap fill is 0.5mm. Using alkoxy-ethyl cyanoacrylates will reduce visible powdery residue on the surface and is less pungent than a regular ethyl cyanoacrylate.

Epoxy adhesive – single component epoxies are unsuitable as the heat required to cure the adhesive will damage the acrylic. However, two-component epoxies will bond acrylic. Many grades will bond; generally, people prefer transparent grades such as ET500, ET515 over black or other opaque products.

MS Polymer – Consider MS Polymers for a flexible bonding solution. Since most acrylic is clear, MS359 CLEAR will provide a good finished appearance.

UV Curable adhesives. Many grades of acrylic are UV stabilized. So use products that cure with UV and Visible light. Permabond UV632, UV639, and UV645 UV/Visible light cure adhesives. All three of these products will produce a bond that is stronger than the substrate.

Structural acrylics – several grades are available. MMA’s provide very good bond strength but are flammable and have a very strong odor. As a result, they are often not acceptable, so Permabond formulated low odor toughened acrylic adhesives.

To determine the best specific adhesive to bond acylic in your application, please provide some detail to our technical team. Our adhesive advisors will get back to you with a recommendation.

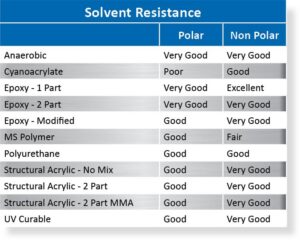

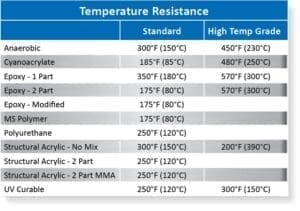

In addition to adhesion to acrylic, understanding the solvent and temperature resistance of the adhesives is especially relevant in selecting the best type of product.

Solvent Resistance

Temperature Resistance

Note: Products can withstand higher temperatures for brief periods providing the joint is not unduly stressed.

1. Providing the surface is clean, dry, and contamination-free, bond the acrylic “As Received.”

2. Engineers often choose to do a solvent wipe before bonding or for clean up afterward and use isopropanol or Permabond Cleaner A. Many solvents, notably acetone, are too aggressive and, as a result, will attack the plastic.

Properties of Acrylic:

It seems like acrylic is found in every industry. A few examples of acrylic uses follow: