Bond nitrile rubber with either Permabond Cyanoacrylates or Permabond Structural Acrylic Adhesives.

Permabond adhesive products found to bond nitrile rubber well are cyanoacrylate adhesives – generally the rubber will tear before the adhesive fails. All grades adhere well to nitrile rubber. If you need some flexibility, consider Permabond 731, 735, 737 or 2050. For other types of rubber Permabond POP increases adhesion – however, Permabond POP does not increase adhesion to nitrile rubber.

Cyanoacrylate adhesives are single component adhesives that polymerize rapidly when pressed into a thin film between parts. The moisture adsorbed on the surface initiates the curing of the adhesive. Strong bonds are developed extremely fast and on a great variety of materials. These properties make PERMABOND cyanoacrylates ideal adhesives for high speed production lines.

1) First, apply the adhesive sparingly to one surface.

2) Then, bring the components together quickly and correctly aligned.

3) Apply sufficient pressure to ensure the adhesive spreads into a thin film.

4) Do not disturb or re–align until sufficient strength develops, normally in a few seconds.

5) Remove excess adhesive with Permabond CA solvent, nitromethane, or acetone.

If you need longer open time or more resistance to polar solvents, opt for Permabond Structural Acrylics for difficult substrates.

Directions for use

1) Surfaces must be clean, dry, and grease-free prior to bonding.

2) Apply a thin bead of adhesive pre-mixed through a static mixer nozzle.

3) Assemble components and clamp.

4) Do not unclamp until you reach the handling strength. The time required will vary according to the joint design and surfaces being bonded.

5) Allow 24-36 hours for the adhesive to fully cure.

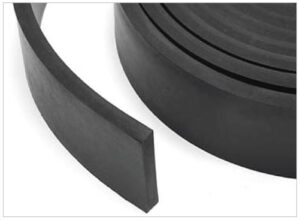

Nitrile rubber is a synthetic rubber – (NBR or XNBR). It is a relatively flexible rubber and its use is widespread. It has a low surface energy combined with a low cohesive strength existing on the surface. Surface treatment techniques such as corona, flame, acid etching etc. have very little effect.