What is ABS? = Acrylonitrile Butadiene Styrene. This is a common thermoplastic that is rather easy to bond. Which ABS adhesive is best? Various types of plastic adhesives (plastic glues) bond ABS. A few of the most common include cyanoacrylate, 2 component epoxy, structural acrylic, and UV curable adhesives.

All grades of cyanoacrylates, two-part epoxies, polyurethanes, and structural acrylics bond ABS. Consider MS polymers for a flexible solution. In addition to all of the above, UV curable adhesives form strong bonds and can be considered providing light can reach the bond joint.

To determine the best specific ABS adhesive for your application, please provide some detail to our technical team, and we will get back to you with a recommendation.

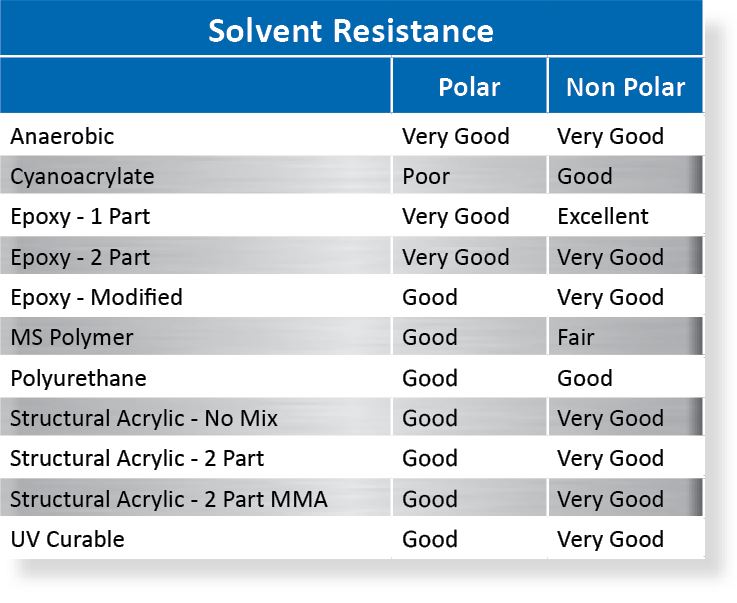

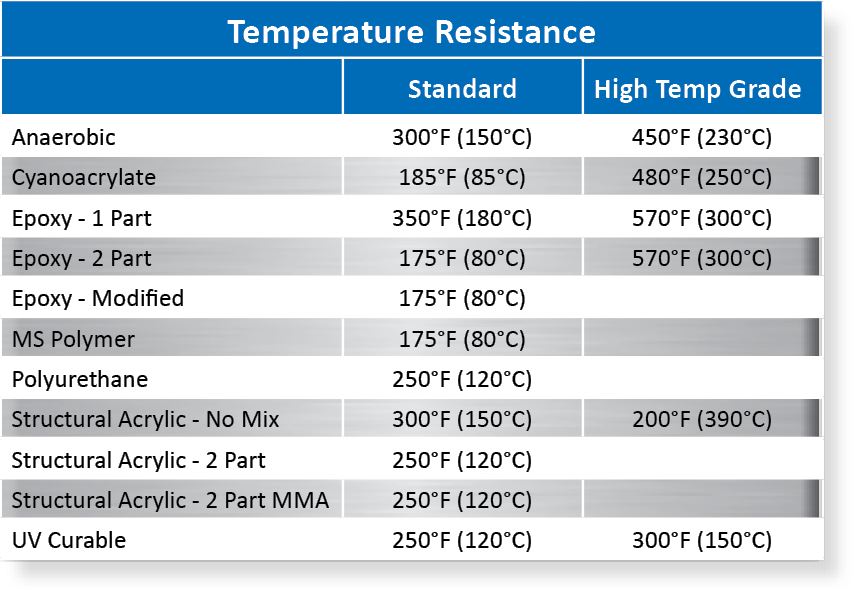

Or, the following charts might help choose the best type of ABS adhesive. Does your application require solvent or temperature resistance?

How to glue ABS? Once we’ve narrowed down the type of chemistry and select a product, there are directions for use on each technical datasheet.

Bond ABS – Solvent resistance of adhesive types

Bond ABS – Temperature resistance of adhesive types

Note: Products can withstand higher temperatures for brief periods providing the joint is not unduly stressed.

1. Generally, if the ABS surface is clean and dry, and free from contamination, bond ABS “As Received.”

2. However, if you wish to do a solvent wipe before bonding or for clean-up afterward, use isopropanol or Permabond Cleaner A. While acetone is an excellent cleaner, it can be too aggressive and consequently will attack the plastic.

ABS Properties:

Surface energy: 42 mJ/m²

Maximum service temperature: 89°C

Softening temperature: 100°C

Normally opaque but clear grades are available

Because clear grades are often UV stabilized (hence they don’t transmit UV light), it is best to check for UV light transmission. If UV light isn’t transmitted, a UV-Visible light cured product can be used.

Trade names: LUSTRAN® ,CycolacTM, Terluran, Magnum CLR95

Cycolac is a trademark of SABIC or its subsidiaries or affiliates.

Lustran® is a registered trademark of INEOS ABS (USA) Corporation.

TERLURAN is a registered trademark of BASF Corporation or BASF SE.