Cyanoacrylate Directions for Use Video

Surface Preparation Directions for Use Video

Cyanoacrylate adhesives are single component adhesives that polymerize rapidly when pressed into a thin film between parts. The moisture adsorbed on the surface initiates the curing of the adhesive. Permabond 922 develops strong bonds extremely fast and on a great variety of materials. These properties make PERMABOND cyanoacrylates the ideal adhesives for high-speed production lines.

Surface Preparation prior to bonding with Permabond 922

Surfaces should be clean, dry and grease-free before applying the adhesive. Use a suitable solvent (such as acetone or isopropanol) for the degreasing of surfaces. Some metals such as aluminum, copper, and its alloys will benefit from light abrasion with emery cloth (or similar), to remove the oxide layer.

Permabond 922 Directions for Use

1) Apply the adhesive sparingly to one surface.

2) Then, bring the components together quickly and correctly aligned.

3) Apply sufficient pressure to ensure the adhesive spreads into a thin film.

4) Do not disturb or re-align until sufficient strength is achieved, normally in a few seconds.

5) Remove any surplus adhesive with Permabond CA solvent, nitromethane, or acetone.

NB:

For difficult or porous surfaces using a Permabond activator is recommended. If bonding polypropylene, polyethylene, PTFE, or silicone, prime first with Permabond Polyolefin Primer (POP).

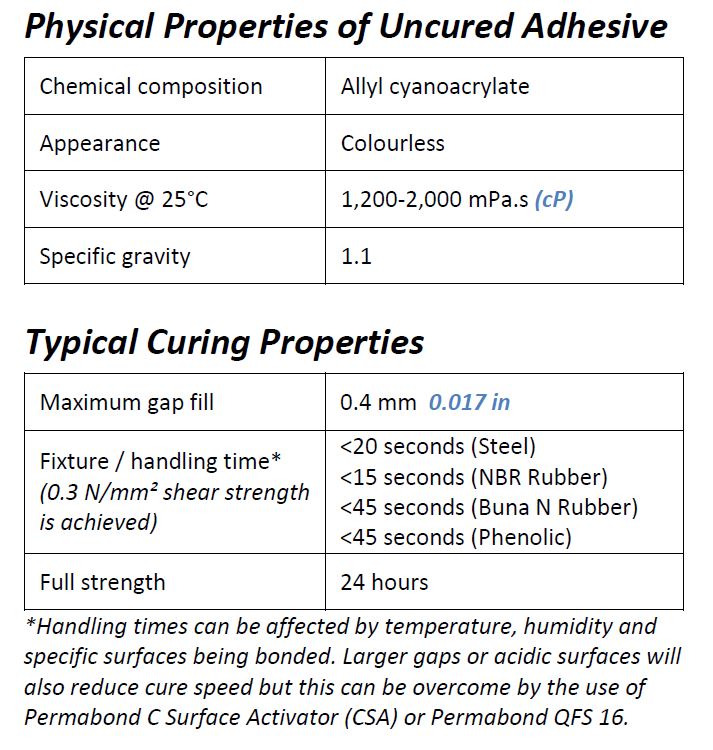

For more information, download the Technical Data Sheet.