CRP is a composite material with extremely high structural strength making it popular for high impact or highly stressed applications.

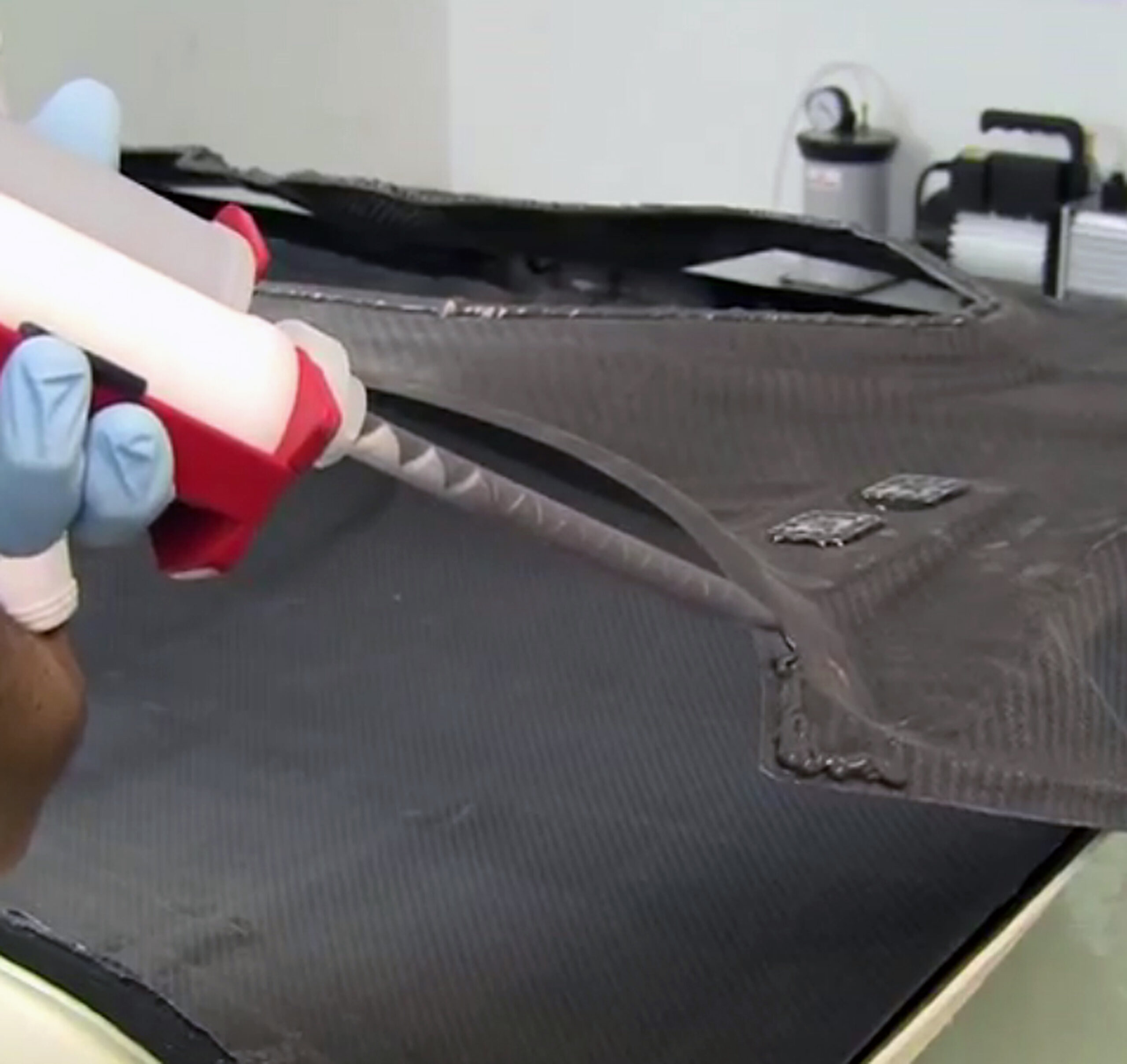

It is lightweight, and there is a strong requirement for adhesives for bonding this material as it cannot be welded, and mechanical fasteners

not only add to the component weight, rattling, and vibration loosening but can affect the structural integrity of the material if it has to be drilled.

CRP Uses

Tips for surface preparation:

1. Degrease with Permabond Cleaner A or isopropanol (do not use meths or white spirits as this can leave a residue).

2. Lightly abrade by one of the following methods

-Wet and dry grit paper (carborundum paper) 320 grade recommended.

-Red Scotchbrite pad

3. Degrease again to remove any contamination or loose particles.

It is OK to bond as received but if you wish to have a consistent bonding surface and better mechanical keying of the adhesive, then carrying out this surface preparation is recommended.

Cyanoacrylate – also known as instant adhesives, super glue, crazy glue, ca glue, etc. For bonding carbon fiber reinforced polymer, consider a black, toughened grade such as 735 low viscosity or 737 medium viscosity.

Single component epoxies – Permabond ES5681 is ideal for bonding carbon fiber. Offering high strength structural performance as well as color matched appearance. Permabond also offers low viscosity clear ES560, which can encapsulate fibers.

Two component epoxies – Permabond ET5428, ET5429, and MT382, MT3821 have been developed specifically for bonding CRP.

Structural acrylics – MMA grades such as TA4246 are very strong carbon fiber bonders.

Polyurethane adhesives – All Permabond polyurethane adhesives offer high strength, high peel strength, and good impact resistance.

With so many choices of adhesives to bond carbon fiber, the desired cure process, environmental resistance, and temperature resistance are key factors in choosing the best adhesive for each application.

Contact Permabond for an adhesive recommendation for your application.